Description

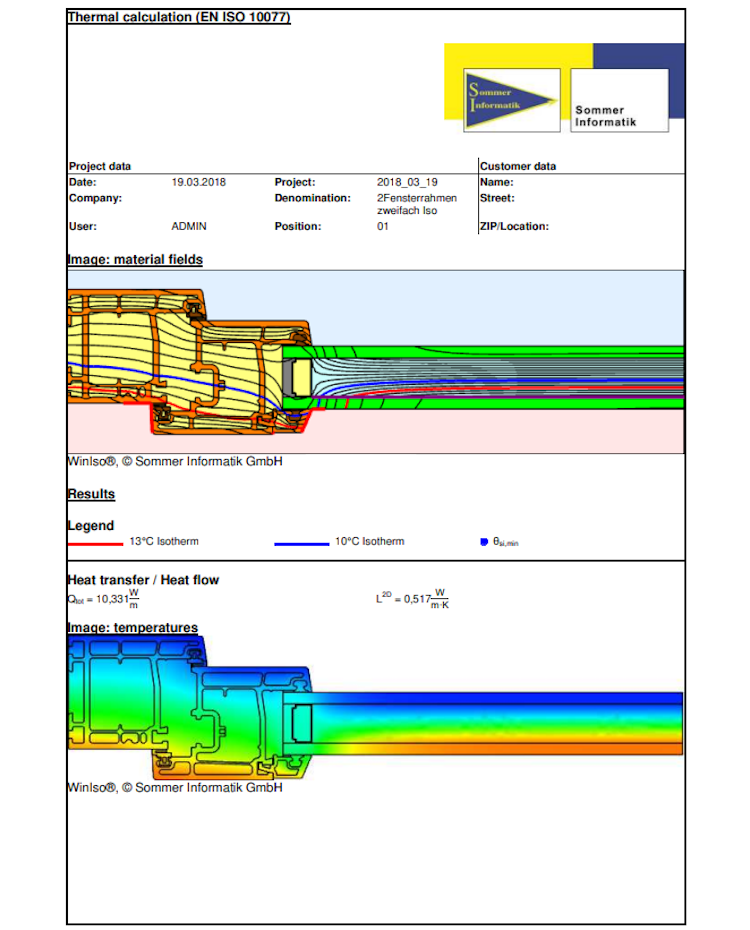

WINISO® is the expert software for the calculation of heat flows, thermal bridges, isotherms and Uf values according to EN ISO 10077-2:2018. Imported CAD files can be processed with automatic recognition and correction of CAD errors. Thus, complicated components and systems can be analyzed and calculated with short computing times and small data sizes. The integrated CAD editor and the FEM calculator core, in combination with the validated calculation method and the new ISO 10077-2:2018 standard, enable the user to achieve a very accurate calculation result. After over a year of development the new WINISO® is available.

Videopresentation

For more than 20 years, the widely used WinIso2D software has been established in many areas of building physics. New standard specifications and the constant progress in window and facade technology result in increasing demands on the calculation software. The FEM calculator core contained in WINISO® enables a precise and validated calculation of any CAD files in a very short time. Users of WinIso2D will not only find all the usual functions in the new software, but also the processing and calculation possibilities will be extended by numerous features, which describes only one of the many advantages of the new WINISO.

The software solution „WINISO®“ includes the following features:

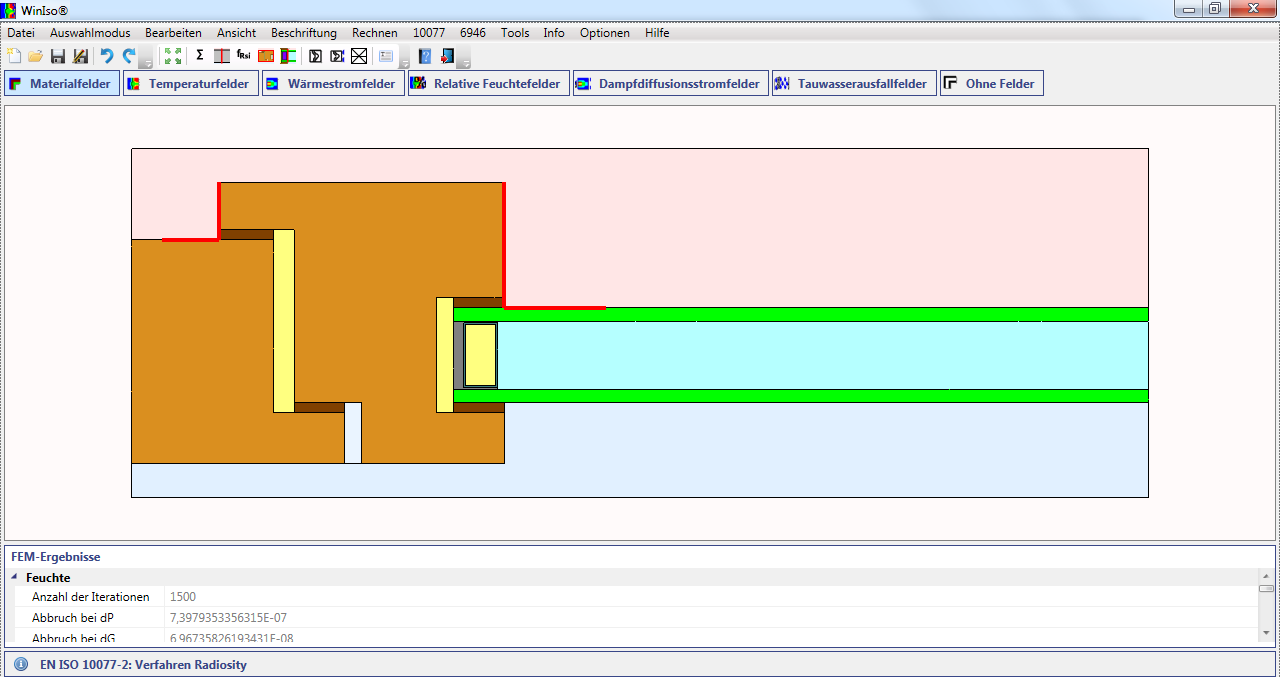

- Highly automated geometry preparation of CAD data (.dxf und .dwg)

- Detailed transfer of CAD data incl. radii and bevels

- Automatic material assignment using CAD layers

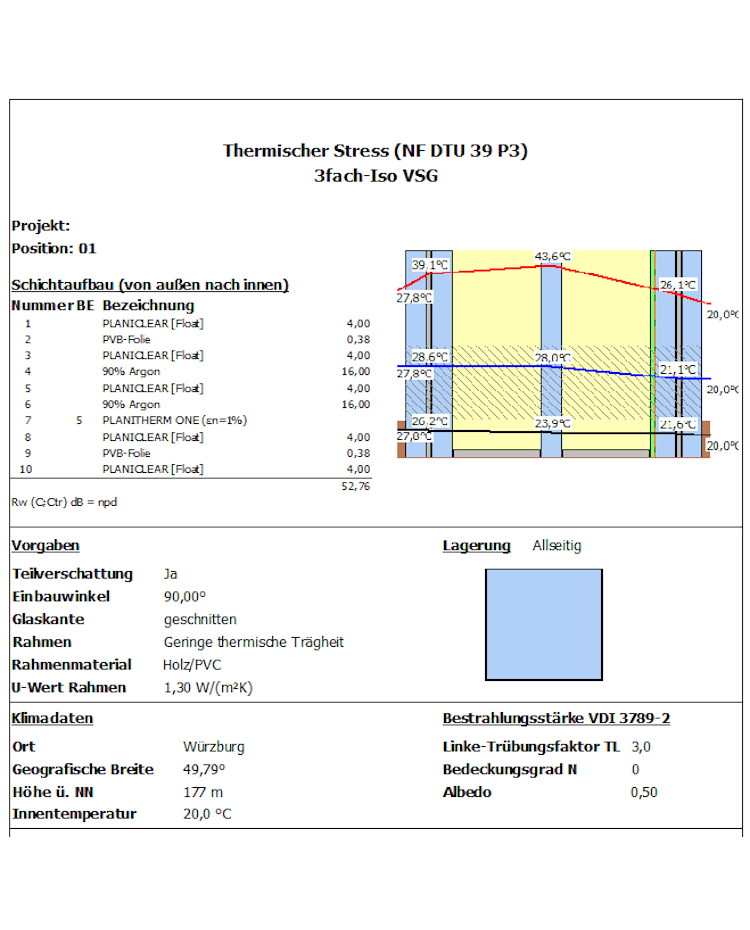

- New solver and new calculation core with automatic FEM networking

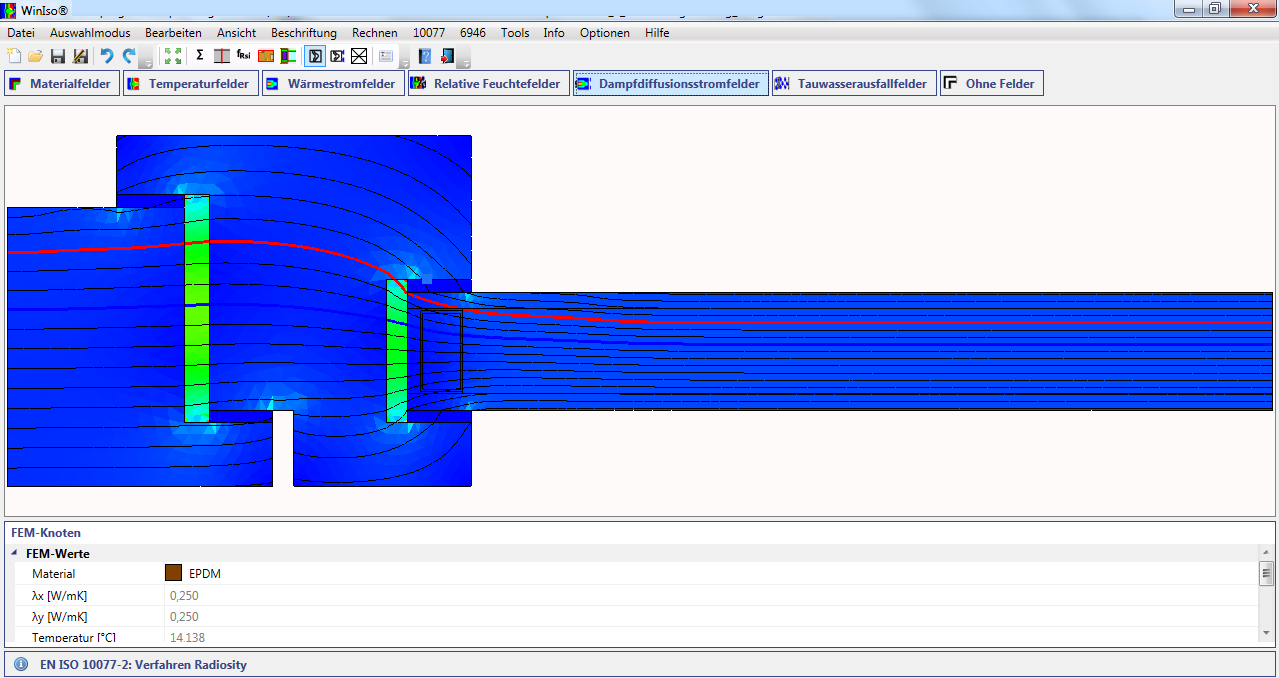

- Calculation according to the “radiosity model” (new cavity model according to

EN ISO 10077-2:2018) and with equivalent conductivity (EN ISO 10077-2:2012/

2018) - Simple definition of foils, coatings and surface properties using polylines

- Gas filling for inter-pane spaces according to EN 673 freely miscible

- Automated Uf calculation of window and facade profiles

- Psi values of thermal bridges and insulating glass spacers according to EN ISO

10211 and EN ISO 10077-2 - Ug values of multiple panes of insulating glass according to DIN EN 673

- U-values of any construction according to EN ISO 6946

- Calculation of isotherms, surface temperatures and temperature factor

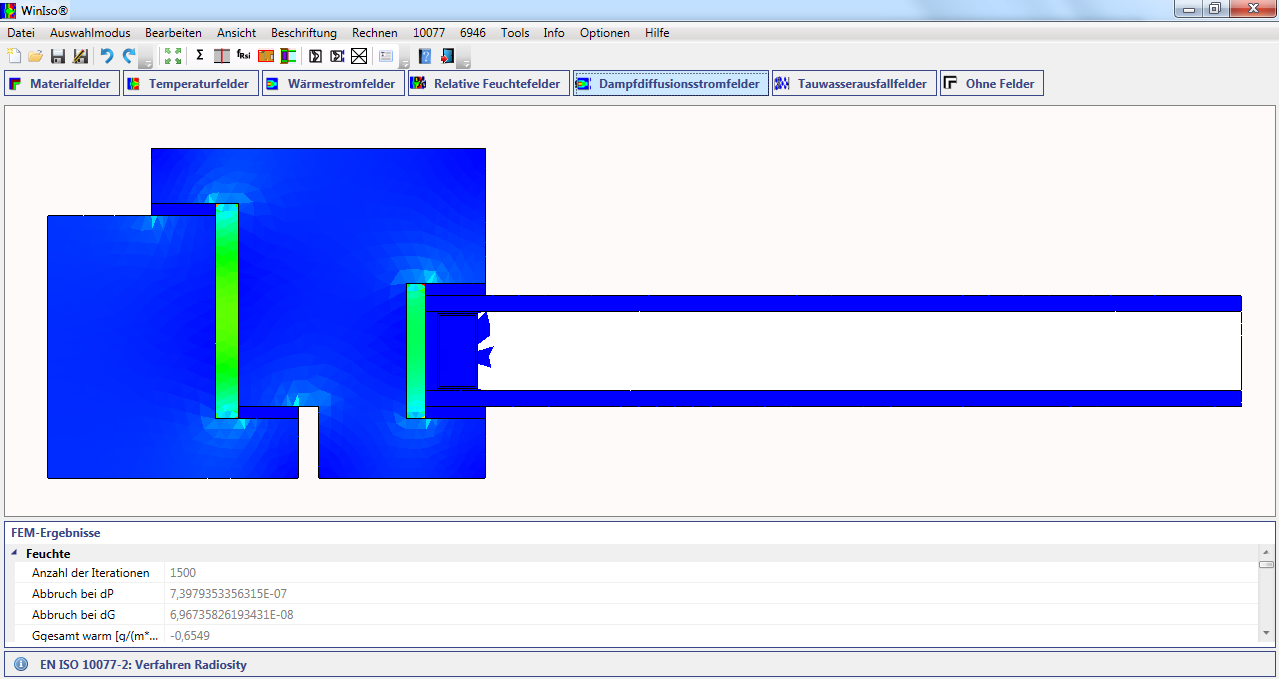

- Vapor diffusion calculation